A new approach to steel: How Schwarzwald Eisen is shaping the future of steel processing with KALTENBACH

Schwarzwald Eisen has successfully responded to the increasing demands of the steel market by installing a saw drill combination, a shot blasting system and an automated transport system in Karlsruhe. Working closely with KALTENBACH ensured that the project was implemented quickly and efficiently. Permanent support from the Service Help Desk keeps the system up and running and demonstrates the reliability of KALTENBACH solutions, which steel supplier Schwarzwald Eisen has been relying on for over 20 years.

The project

Our customer

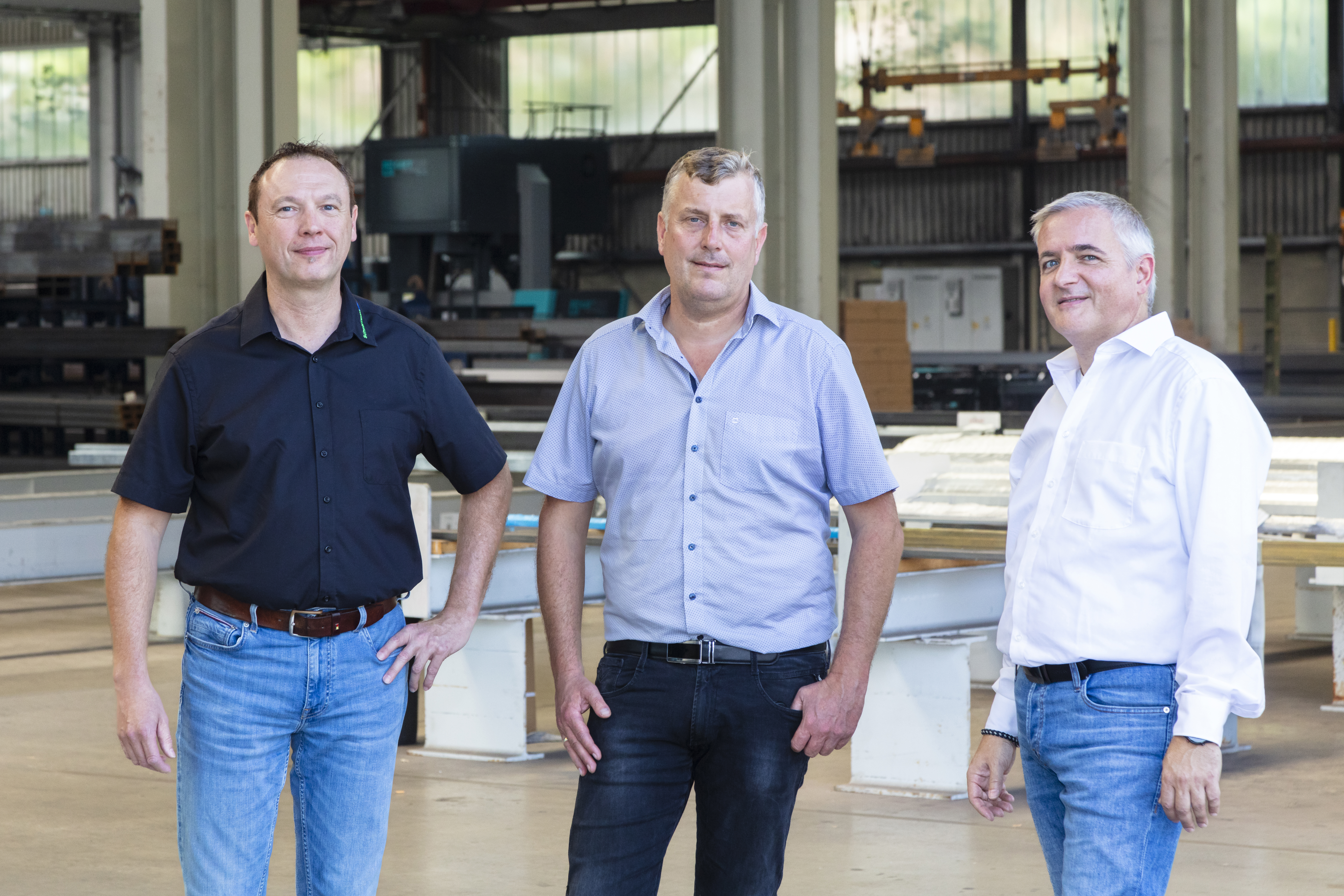

Schwarzwald Eisenhandel GmbH & Co. KG was established in 1966 and has around 450 employees across the entire group of companies. It is headquartered in Lahr and has three other locations in Germany (Bad Säckingen, Freiburg and Karlsruhe). Schwarzwald Eisen manufactures and processes all types of steel products. Profiles and hollow steel sections are processed and preserved in line with individual customers’ wishes. Alongside its activities as a full-range supplier in the steel trade, the company offers an extensive spectrum of processing options.

Challenge for the customer

The steel market is changing. The customers' demands for fast delivery times and high-quality products are constantly increasing. Schwarzwald Eisen has decided to install a further system with a sawing and drilling unit, shot blasting system and automated transport system at the Karlsruhe location in order to be able to meet these requirements in the future - despite the limited space available in the production hall.

The solution

The project was implemented quickly thanks to the close and cooperative partnership between KALTENBACH and Schwarzwald Eisen. The old system was dismantled and the new one installed in a very short time. In order to integrate the machines into the production hall in the best possible way, special attention was paid to a space-saving and effective arrangement of the saw drill combination, blasting and transport systems.

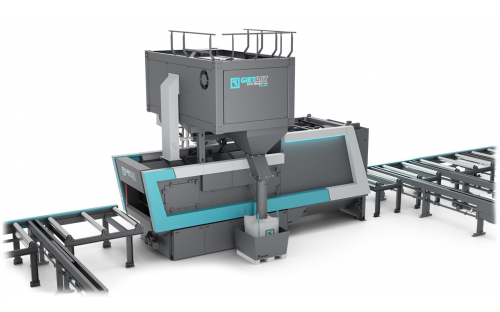

The overall system drills, saws, mills, blasts and cleans a variety of different profiles that are required in steel processing. The processing quality is ensured for both small and large dimensions. The KALTENBACH transport system connects the individual work steps with each other so that a continuous and efficient material flow is achieved.

On top of this, KALTENBACH offers the Schwarzwald Eisen team support from highly qualified service technicians at any time via the help desk. The remote diagnosis option in particular allows the company to react quickly in the event of a fault and ensure operational readiness.

Solution package in detail

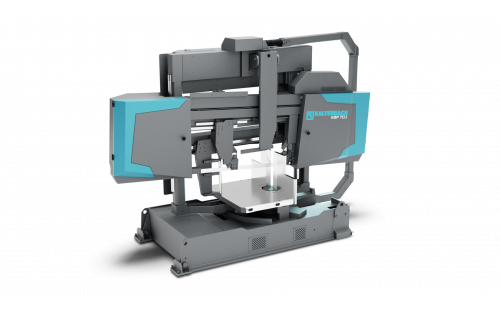

- Saw drill combination KDP 736 and KBP 701

- Shot blasting system GIETART ECO Blaster 1504

- Transport equipment (roller conveyors with cross transports)

Benefits

HOLISTIC

Being an expert in steel processing machinery, KALTENBACH could supply the required systems from a single source, ensuring fast installation and coordinated processes.

COST-EFFECTIVE

KALTENBACH supports Schwarzwald Eisen with a system that is robust, durable, easy to implement and integrate and cost-effective to maintain.

AVAILABLE

Schwarzwald Eisen has permanent access to KALTENBACH's highly qualified technical help desk and receives the best possible support also after commissioning.

Deutsch

Deutsch