Product Portfolio

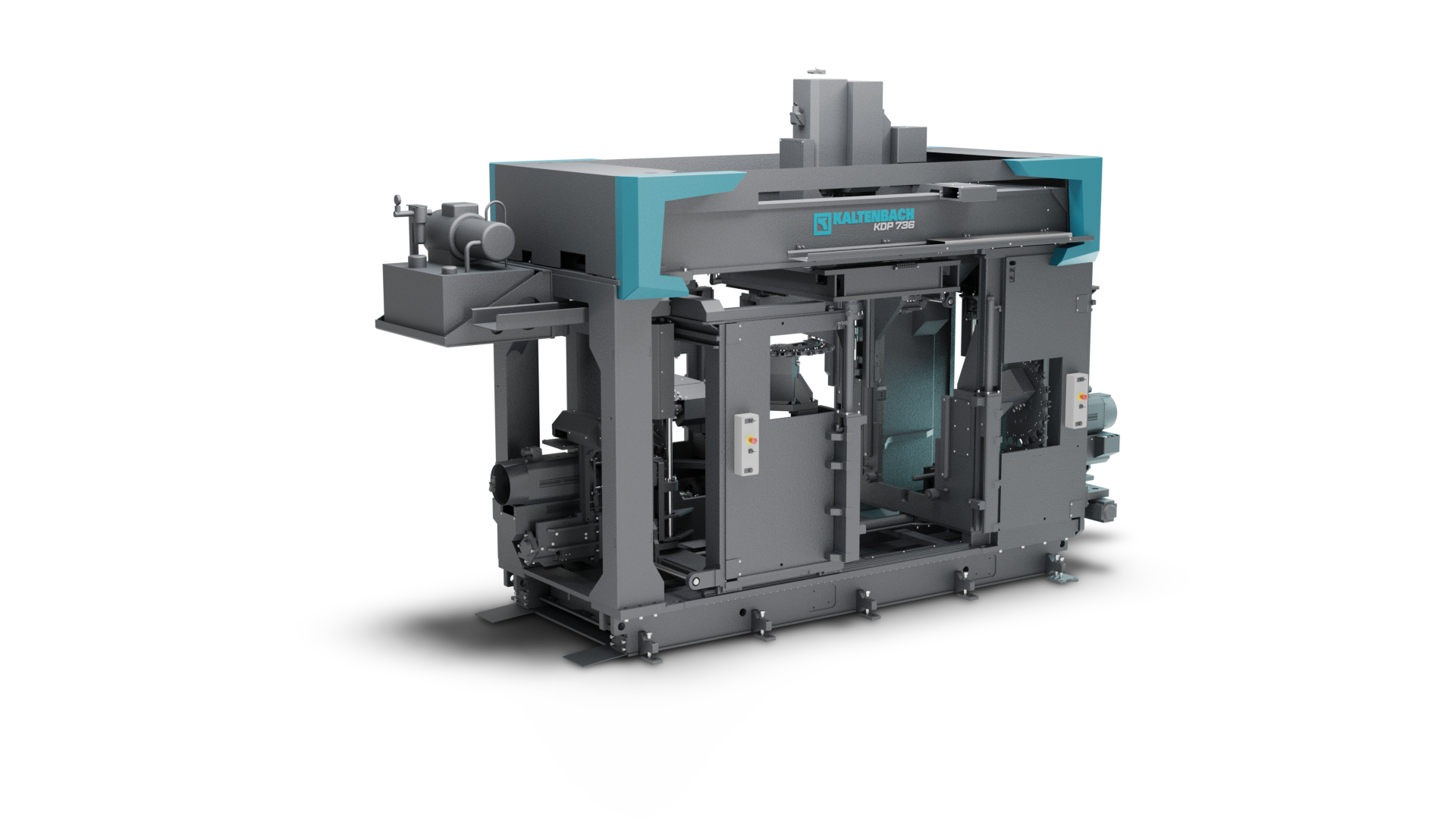

KDP 736

Drill line for medium- and heavy-duty steel fabrication and service centers

Workspace [mm]: 750 x 600 and number of tools: 36

Benefits at a glance

- Robust design for a longer machine lifetime

- Efficient drilling, milling, marking, tapping and countersinking

- Powerful drive for highest processing performance

- Powerful clamping system for a longer tool usage

- Intelligent material measurement for great process reliability

- Servomotors and ball screw for high-precision

- Lager tool changer for 12 tools per axis for less setup times

- Additional sub-axis of 500mm for parallel processing

- Machining while sawing for highest parallization

- Robust machine portal construction

- High rigidity ensures low vibrations for low operational costs

- Very long machine lifetime even under challenging conditions

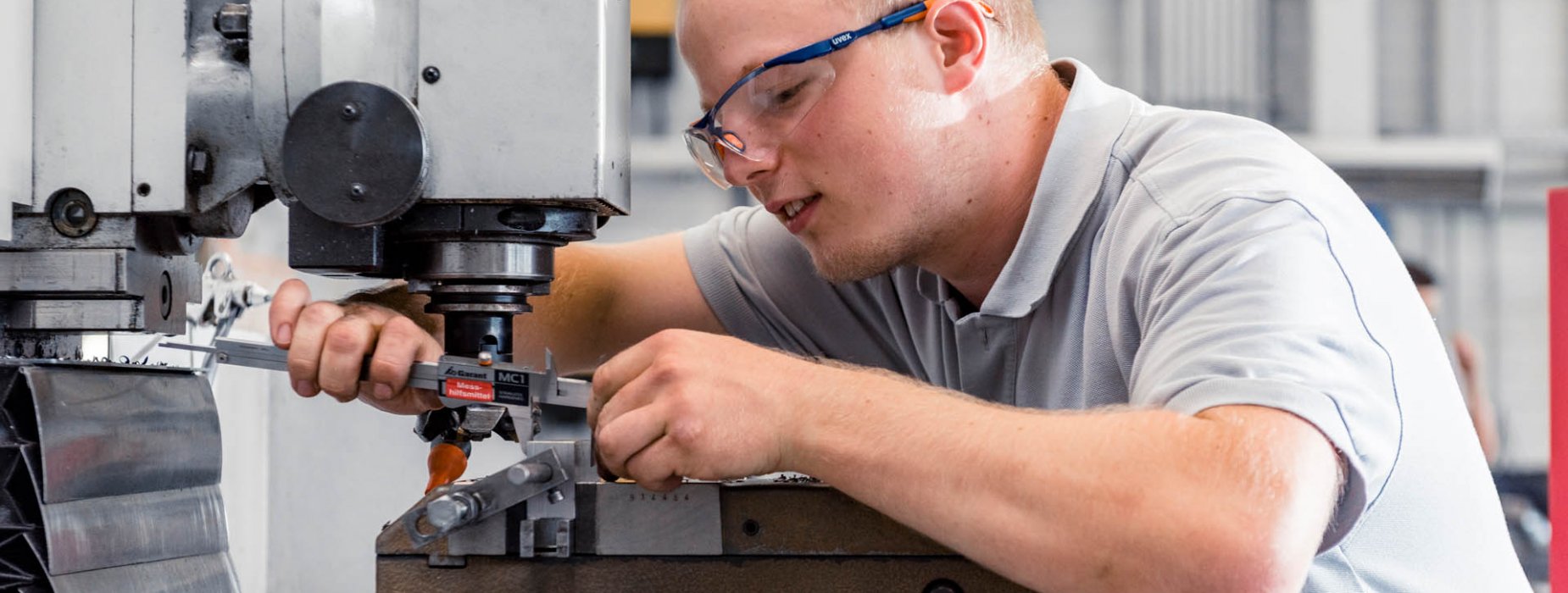

Drill carriages with drill spindles- Robust design for low vibrations and less tool wear

- Fast and precise positioning via ball screw drive and servomoters

Clamping system- Horizontal and vertical clamping system for less vibration

- High clamping power for best fixation and precision

- Less tool wear and thus operational costs

Drilling spindles- Provided Technologies are drilling, milling, tapping, countersinking and marking

- Powerful and fast processing

- Outstanding drilling performance

Automatic tool changer- Fast tool changer for 12 tools per axis

- Low setup time for higher machine utilization

- Automatic tool length measurement

Chip container- Integrated chip container in machine base

- Easy chip handling

- Extractable on both side for full flexibility

Chip conveyor- Automated chip handling

- Higher comfort for operator

Hard stamping unit- Fast marking of numbers and letters

- Mark up to 21 letters without material movement in parallel

- Marking is also visible after shotblasting and painting

Contour marking

Contour marking- Fast and flexible marking for characters and geometries

- Marking on up to 4 material sides

Milling

Milling- Powerful milling features

- Easy operation due to milling macros

Web support- Moveable unit to support the web

- Intensive web processing can be done even on bendabile profiles

Connection to steel roller conveyor

Connection to steel roller conveyor- Cross transport by means of lift-and-carry system (as an alternative to drag chains)

Low-noise material cross transport

Low-noise material cross transport- Due to additional polyamide-coated rollers into the roller conveyor the noise is significantly reduced

- Fully-automatic control

- Contributes to enhanced occupational safety and the protection of personnel and the environment

Space saving measuring system on the feed side

Space saving measuring system on the feed side- M 152 GG sliding measuring carriage with two grippers

Cross transport with lifting pins

Cross transport with lifting pins- Cross transport with lifting pins

Fast material cross transport

Fast material cross transport- Material stock in heavy-duty steel construction

- Sliding rails of synthetic material (polyamide) for low-noise material cross transport

- Drag chains with transport claws

- Drive system with continuously-variable frequency-controlled gear motor

T 14 transport system for steel construction and steel service centers

T 14 transport system for steel construction and steel service centers- T 14 modular expandable conveyor roller system

Universal measuring system on the feed side

Universal measuring system on the feed side- M 151 G sliding measuring carriage with gripper

KDP 1036

KDP 1036The KDP series is specially designed for medium and heavy steel fabrication and service centers. It enables the powerful, automated and comfortable steel processing for highest performance due to parallel processes. It provides all modern processing technologies like milling, carbide drilling, tapping, countersinking and marking.

KDP 1336

KDP 1336The KDP series is specially designed for medium and heavy steel fabrication and service centers. It enables the powerful, automated and comfortable steel processing for highest performance due to parallel processes. It provides all modern processing technologies like milling, carbide drilling, tapping, countersinking and marking.

Efficient steel processing with limited space

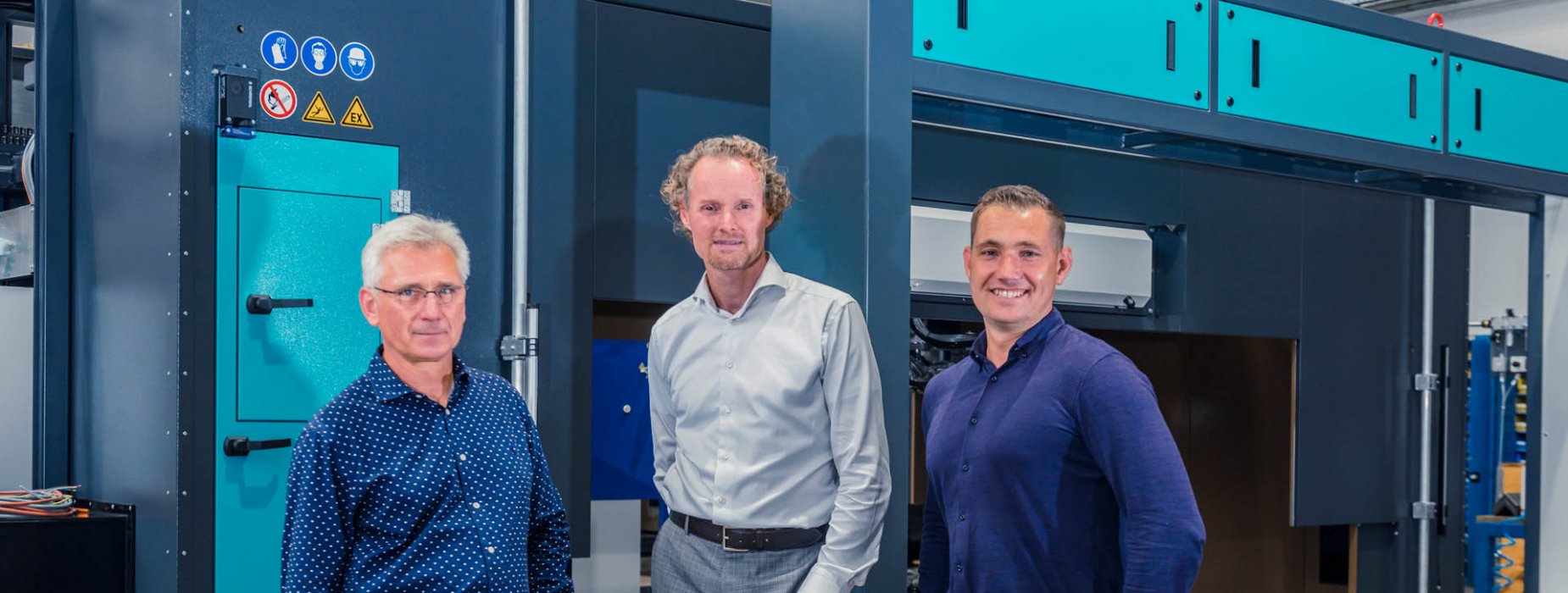

Schwarzwald Eisen has successfully responded to the increasing demands of the steel market by installing a saw drill combination, a shot blasting system and an automated transport system in Karlsruhe.

Read more

We guarantee the quality of your steel!

Environmentally friendly and resource-saving products

Optimal shot blasting results, low running costs

Highly efficient painting and drying systems

Developed for strong performance

Optimal availability and performance

Speed, quality, precision

Trustworthy partnerships

Total design consultancy and customized solutions

We know how to boost your efficiency and productivity

Integrated high-quality solutions for the steel industry

We are there - wherever you need us

Cutting-edge sawing, drilling and plate processing technology

Total versatility, high-end cutting techniques

Over 135 years of accumulated know-how

Automated solutions for each level of requirement

Advanced process monitoring systems

Successful plant integration within your production environment

Constructed to meet your individual needs

Committed support and professional advice

Deutsch

Deutsch