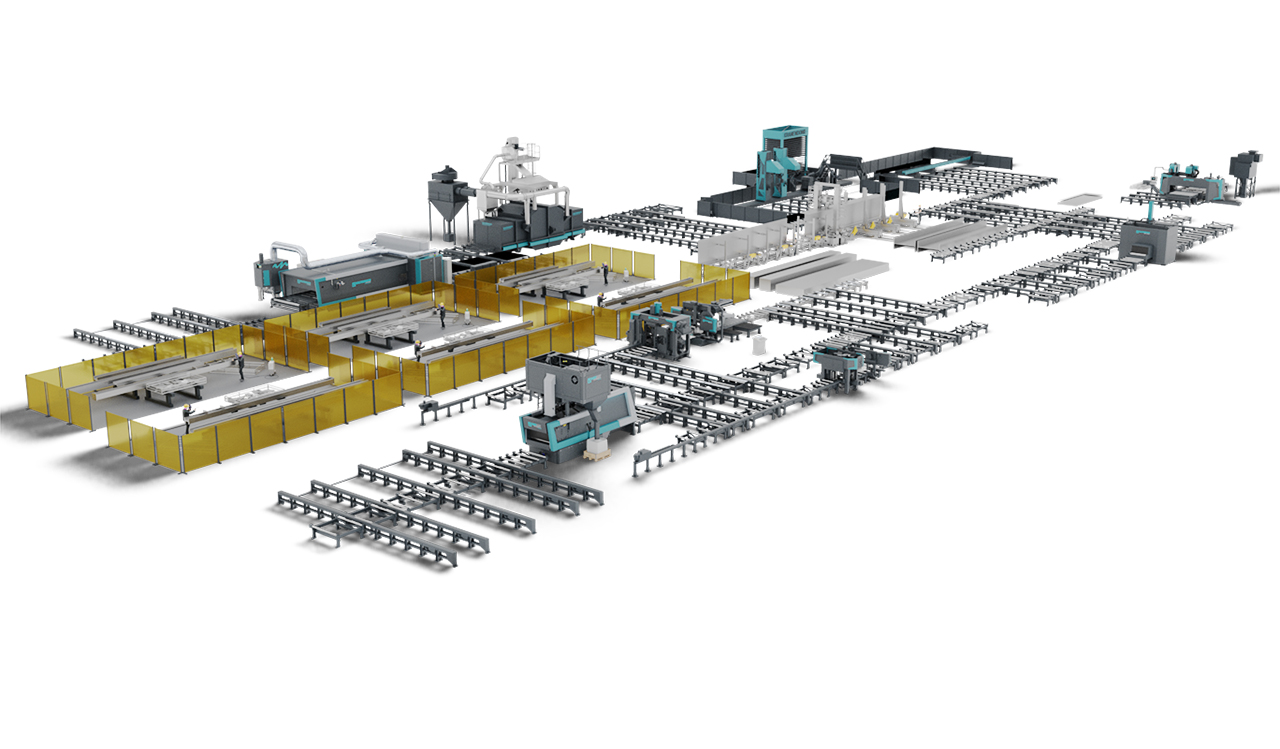

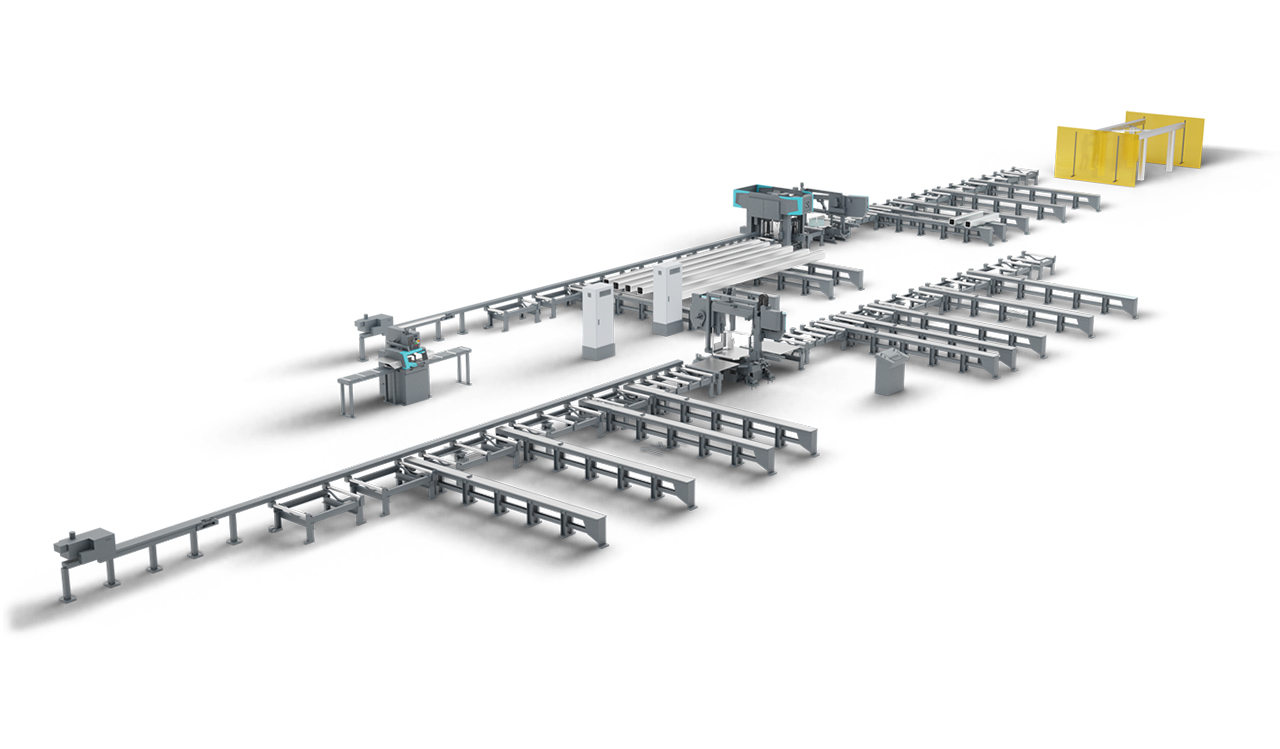

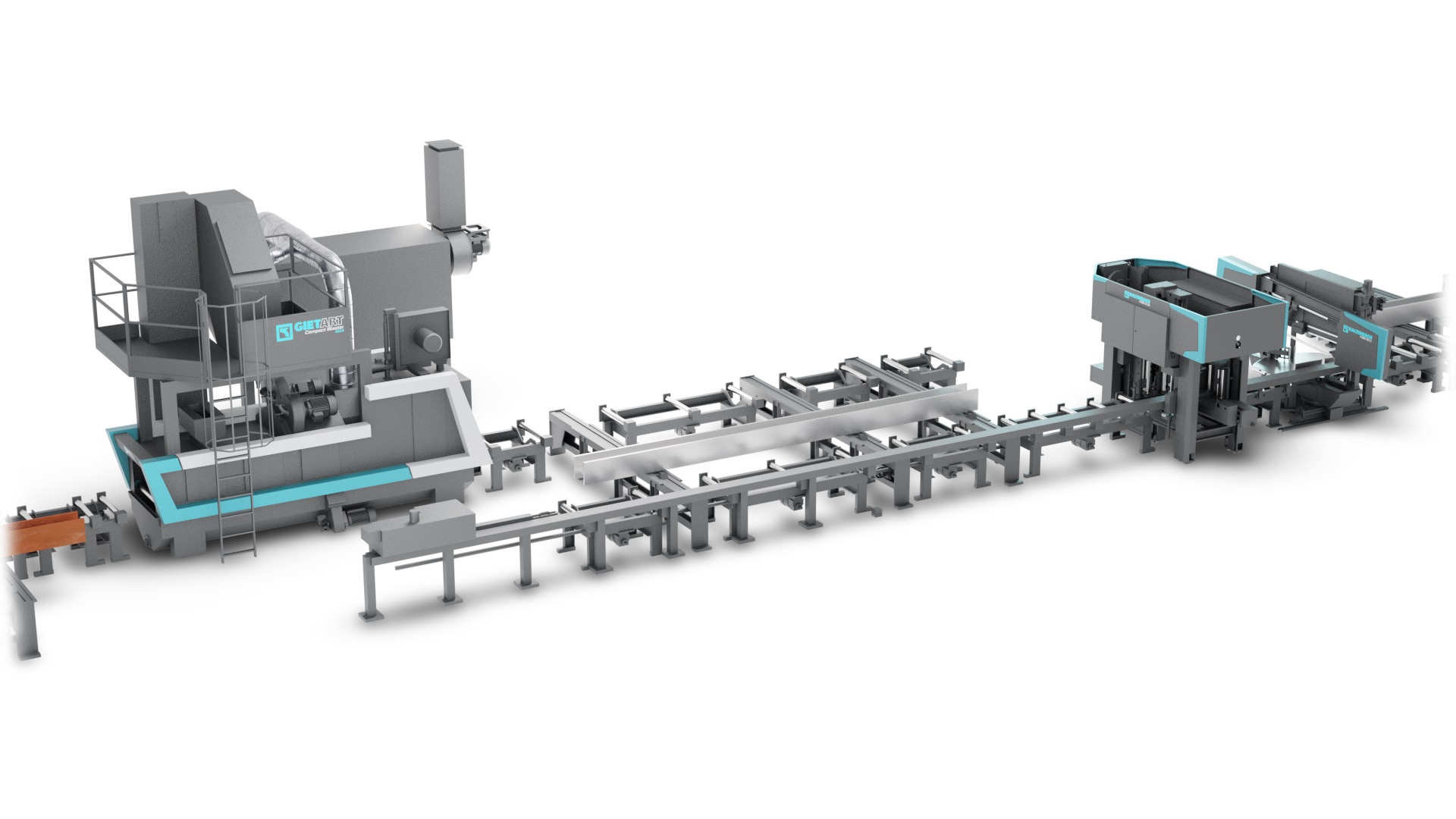

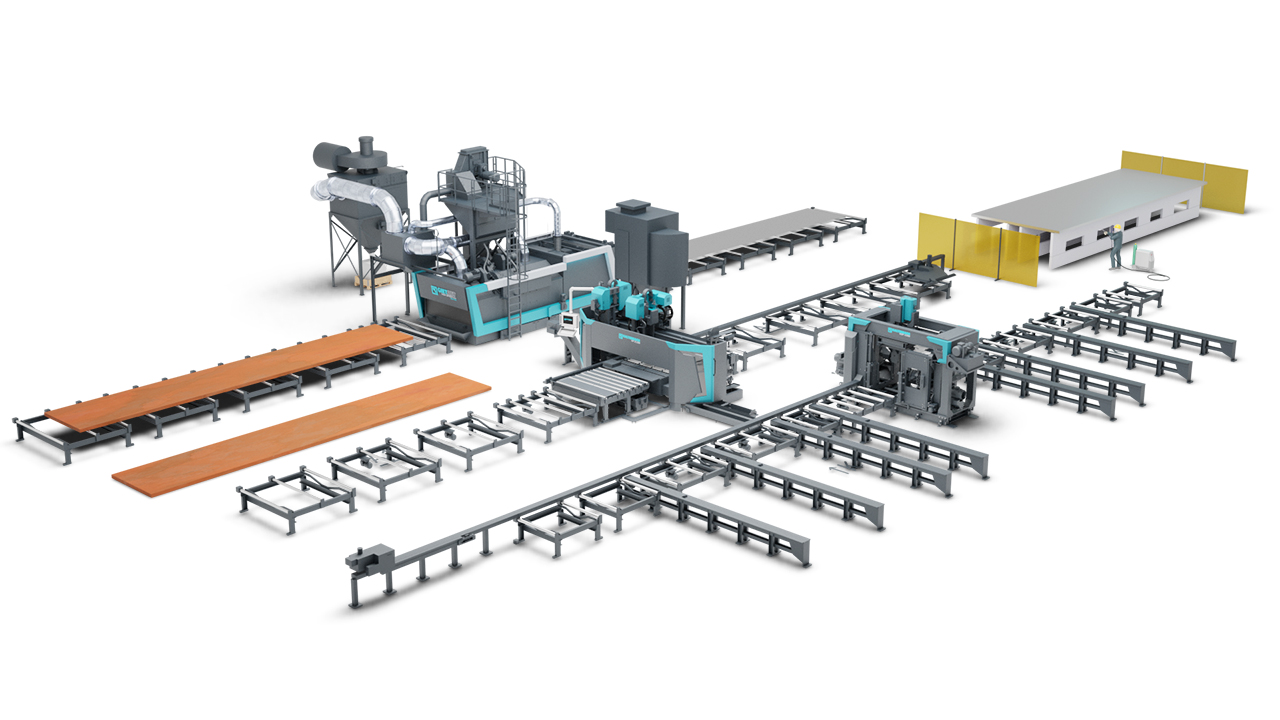

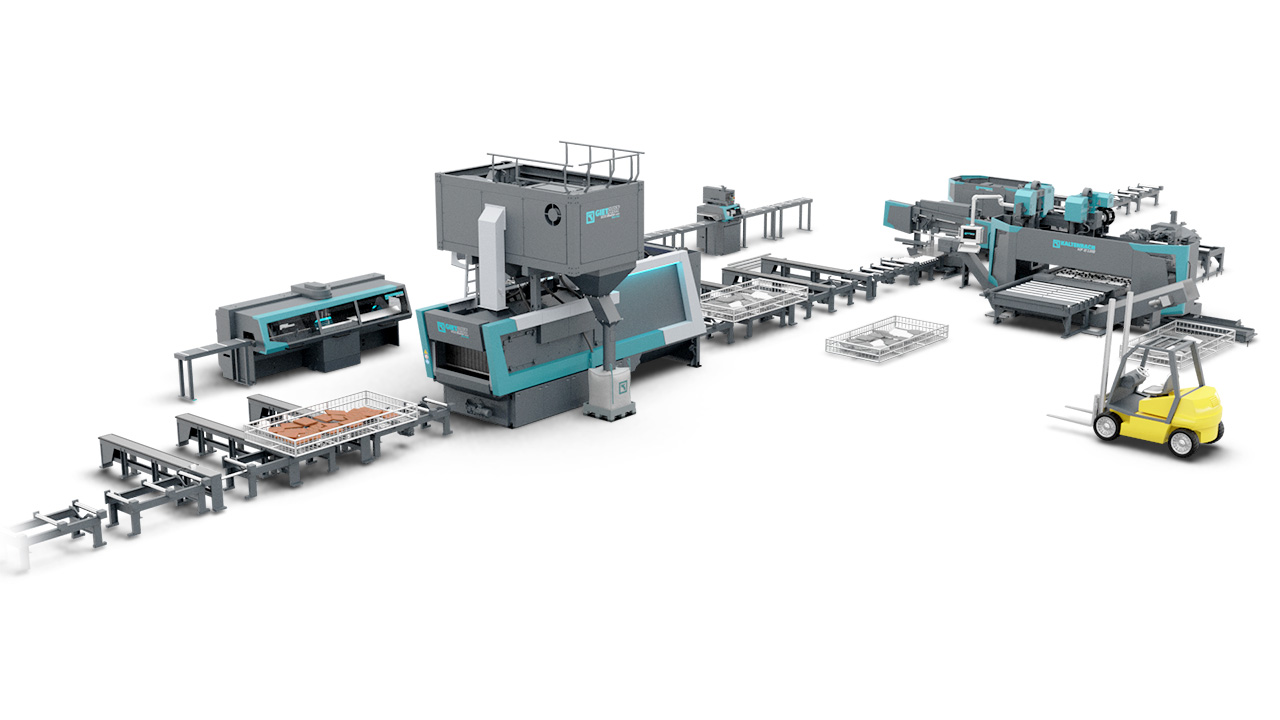

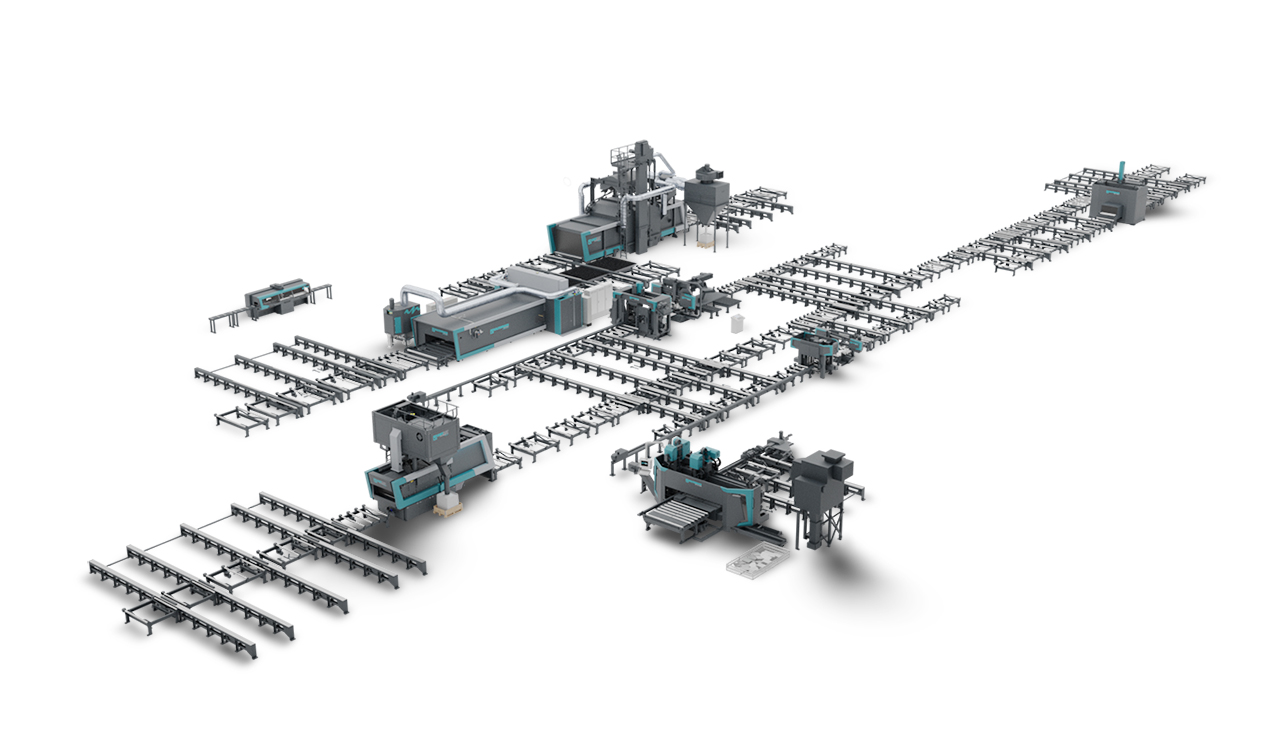

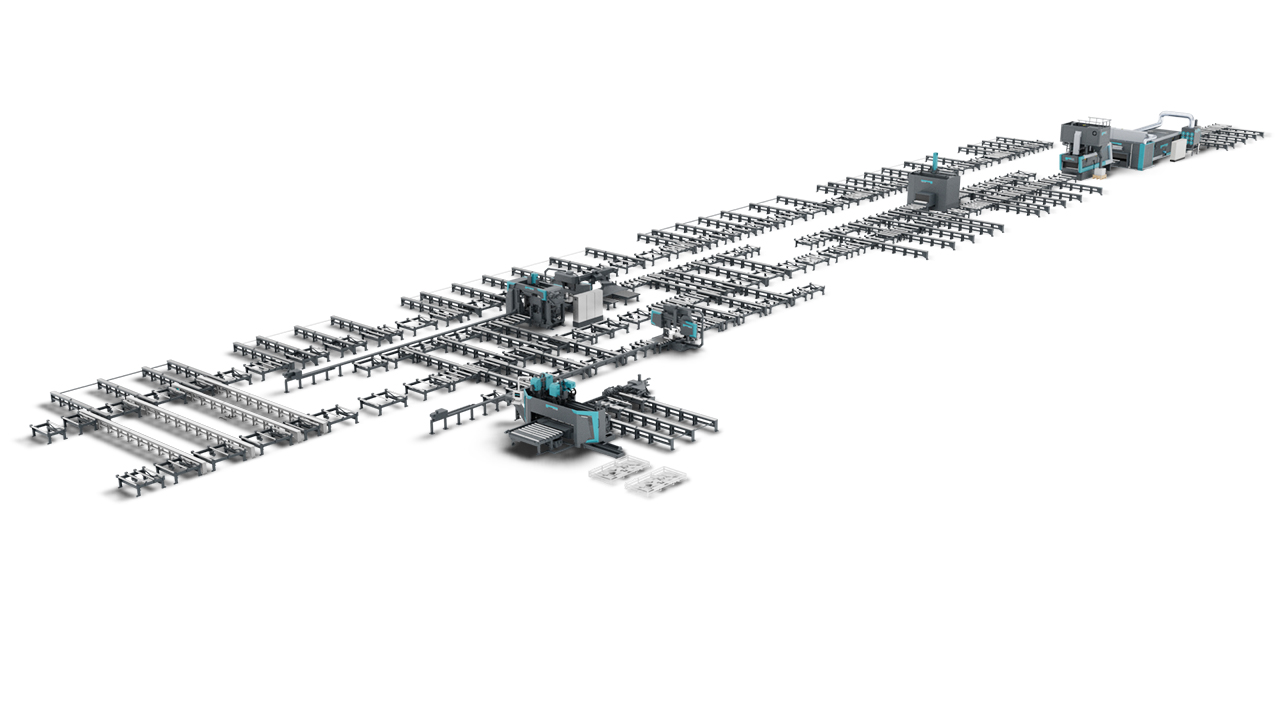

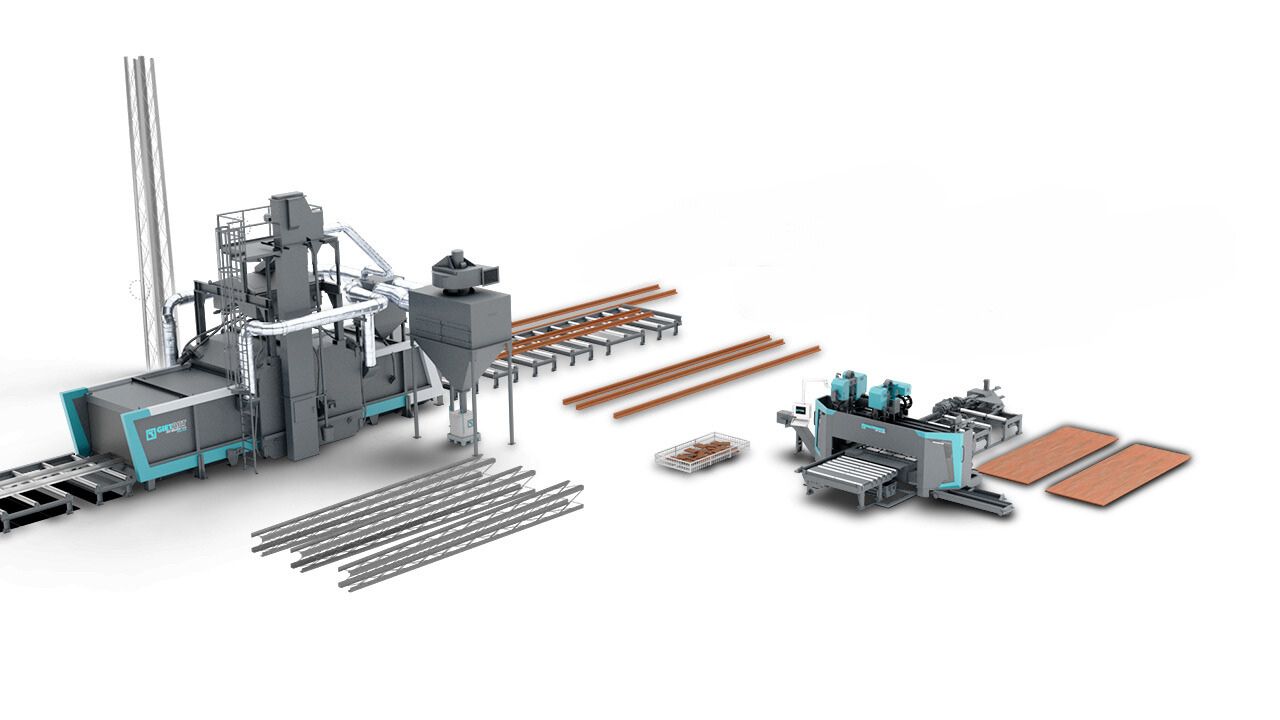

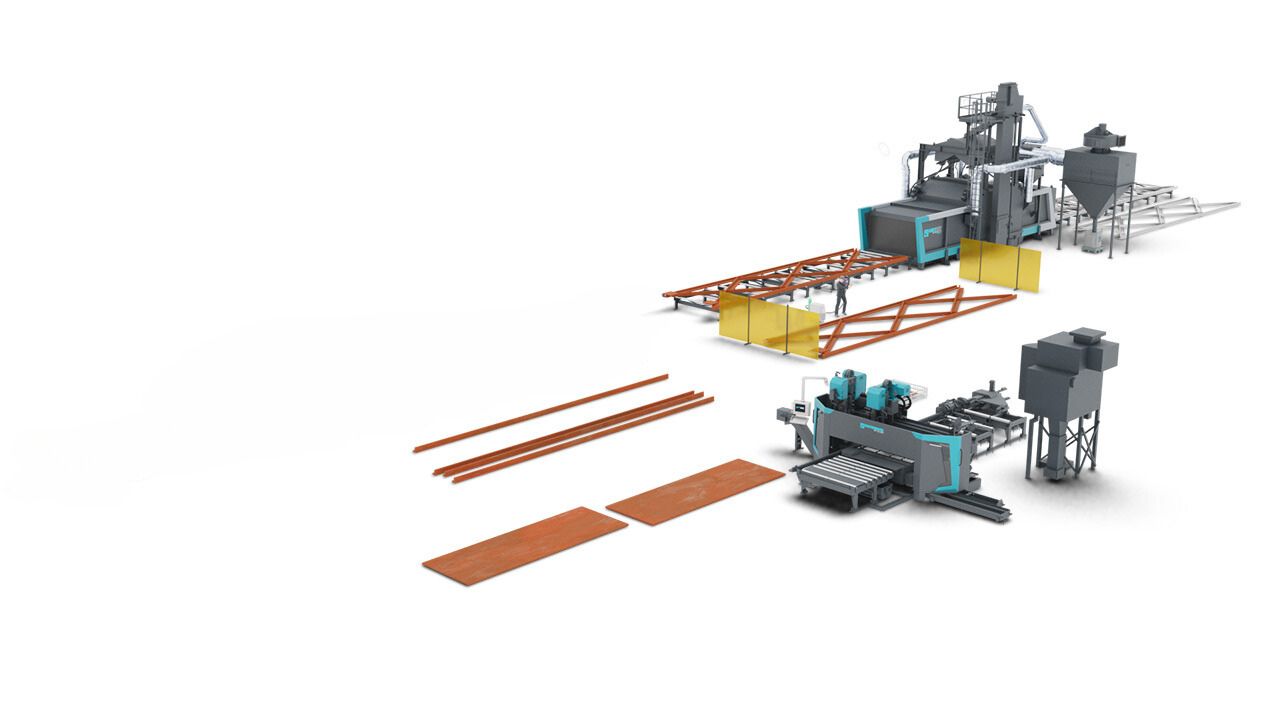

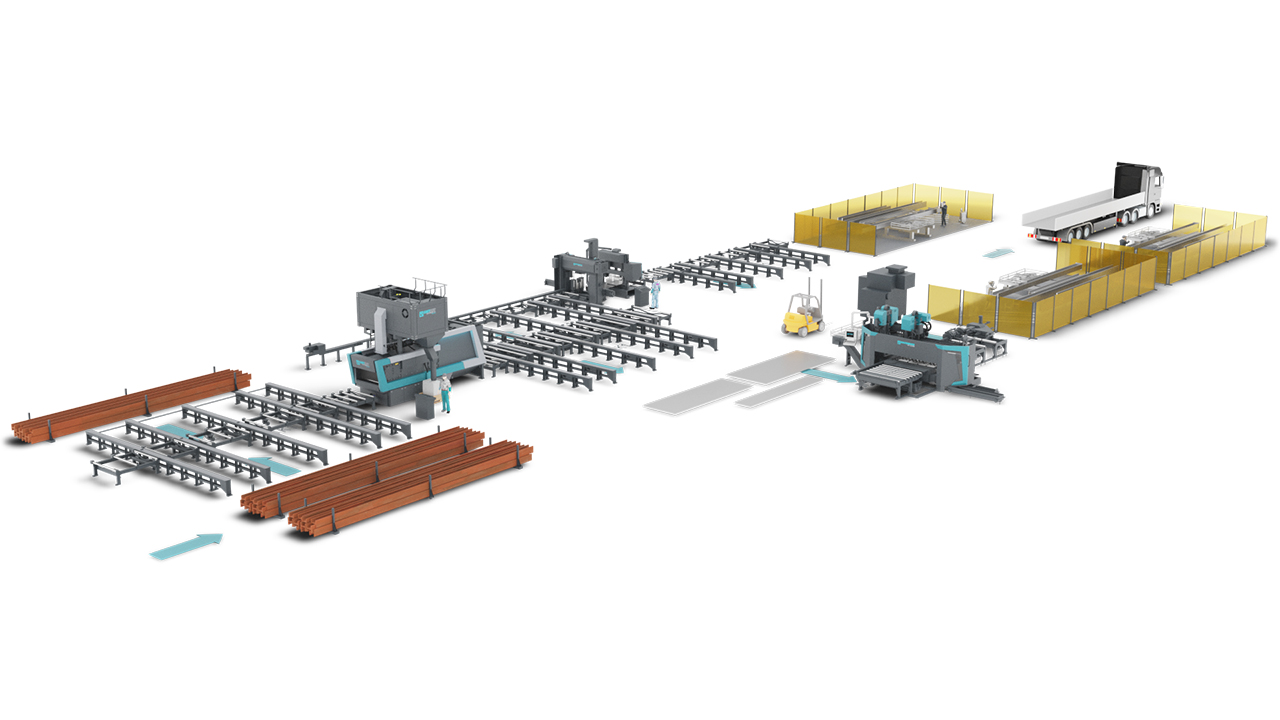

Complete processing lines

Integrated high-quality solutions for the steel industry

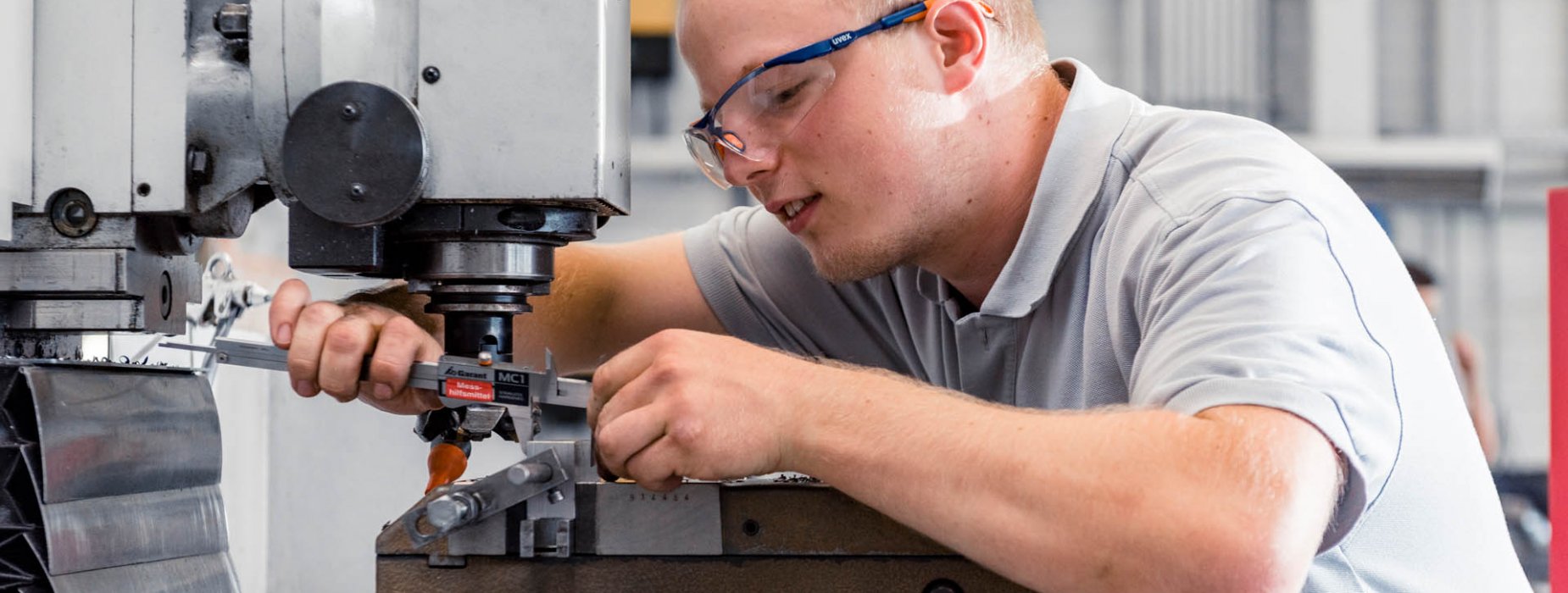

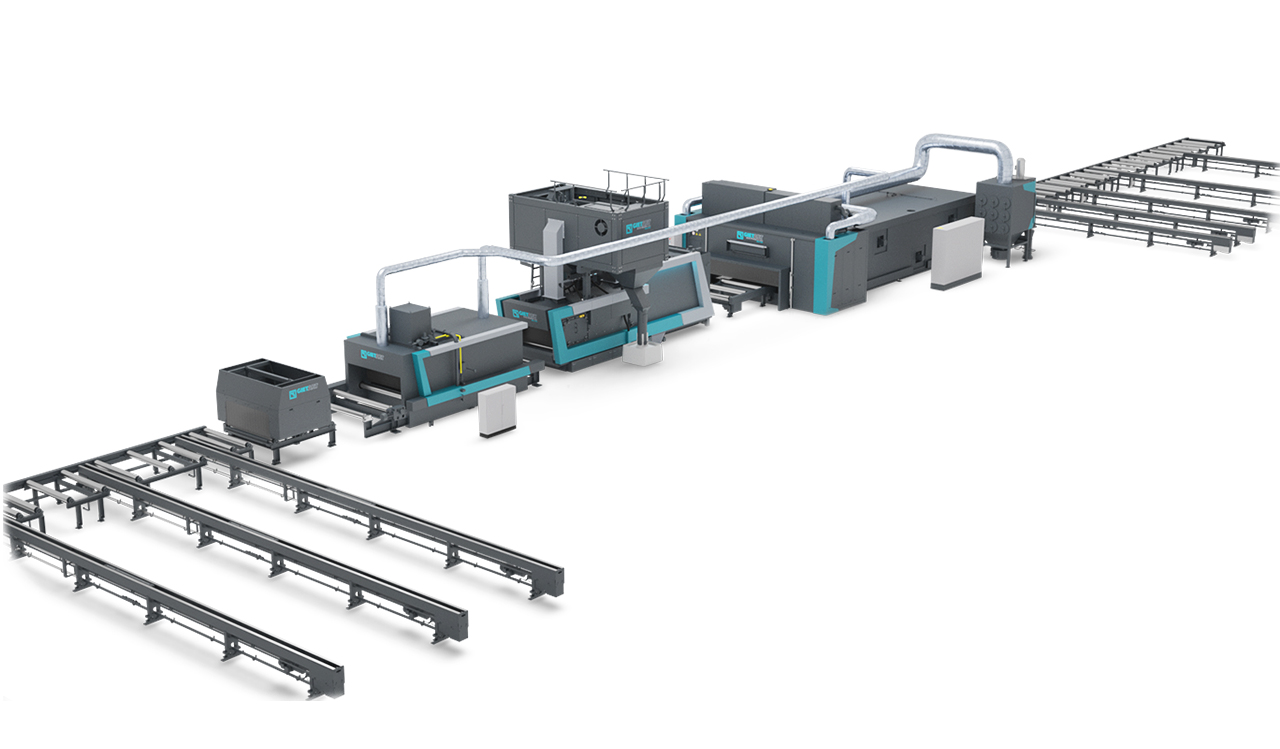

Cutting-edge sawing, drilling and plate processing technology

Over 135 years of accumulated know-how

Automated solutions for each level of requirement

Integrated high-quality solutions for the steel industry

Committed support and professional advice

Trustworthy partnerships

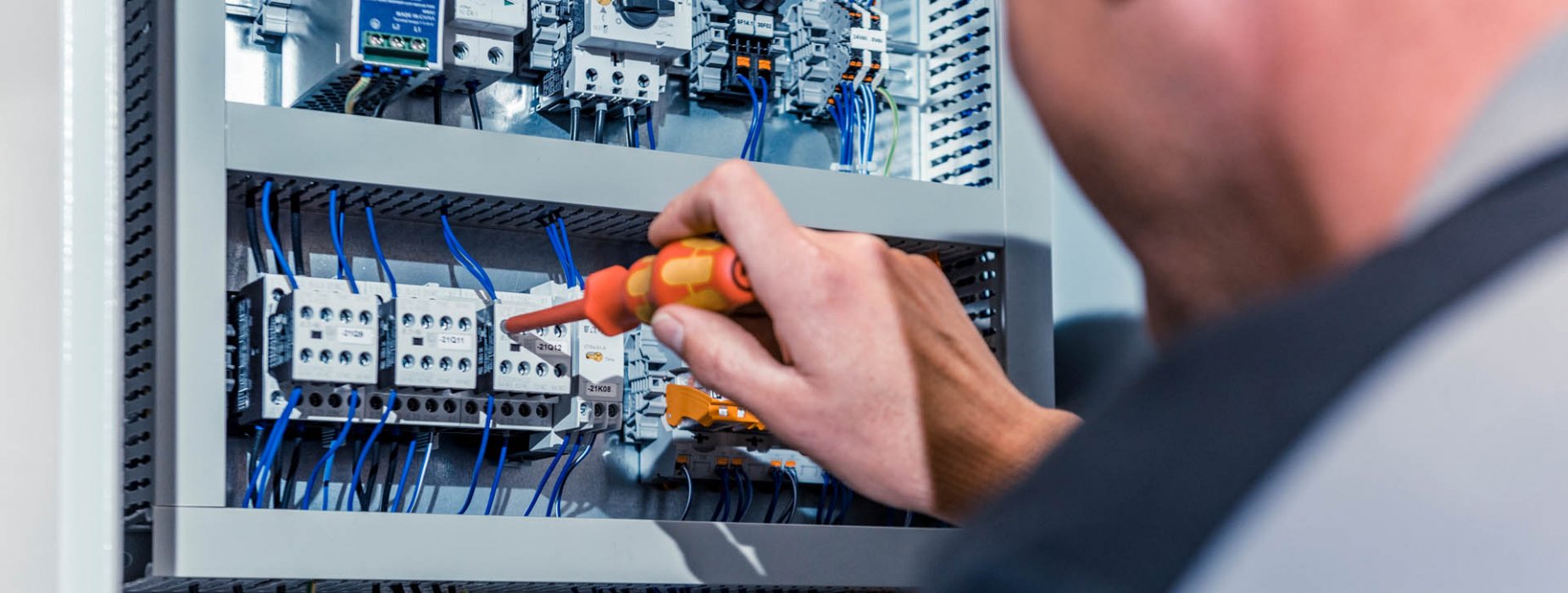

Advanced process monitoring systems

Optimal shot blasting results, low running costs

Successful plant integration within your production environment

Environmentally friendly and resource-saving products

Optimal availability and performance

Total design consultancy and customized solutions

We are there - wherever you need us

We know how to boost your efficiency and productivity

Highly efficient painting and drying systems

We guarantee the quality of your steel!

Constructed to meet your individual needs

Developed for strong performance

Total versatility, high-end cutting techniques

Speed, quality, precision

Deutsch

Deutsch