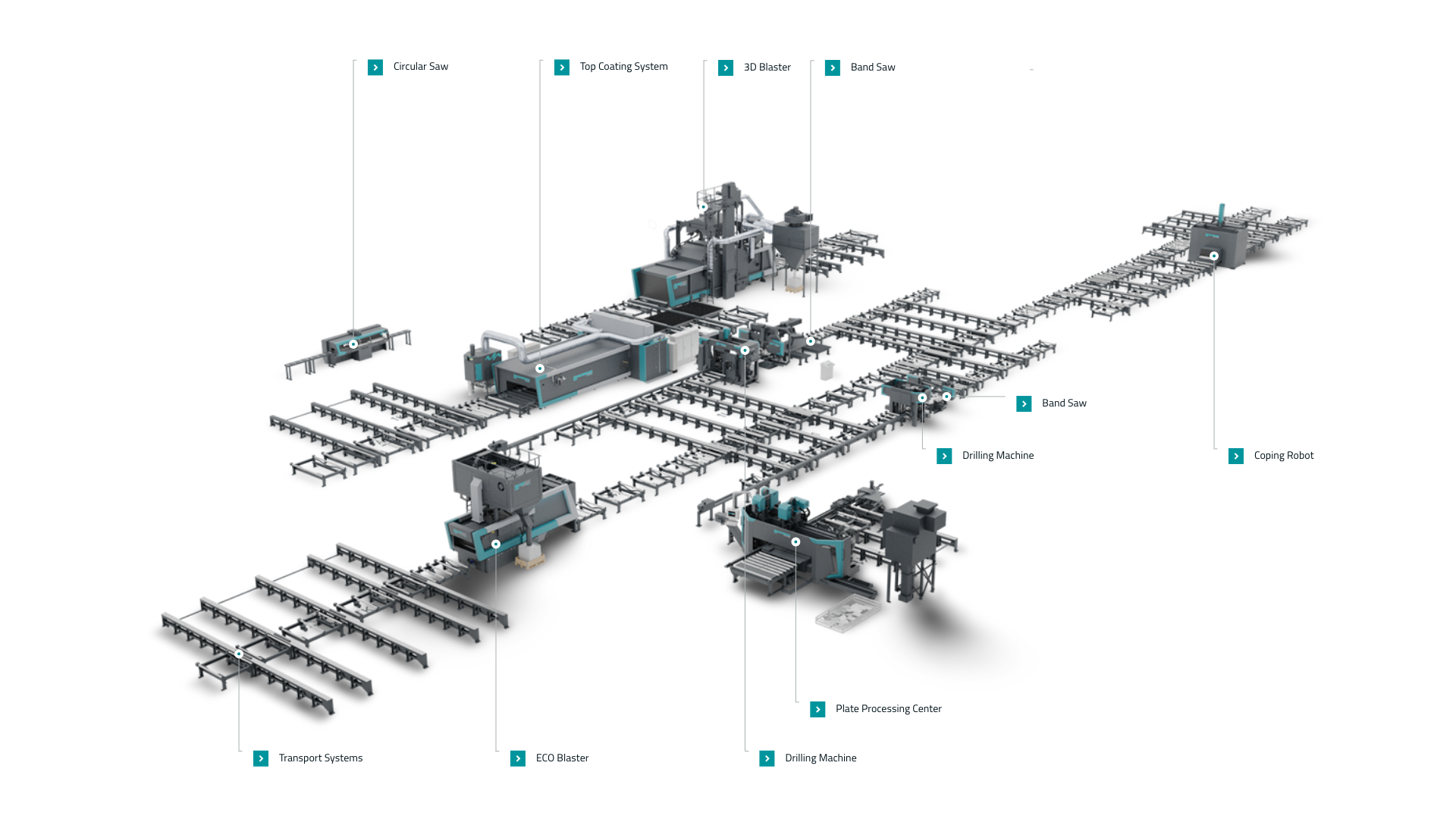

Versatile production of all kinds of steel contructions

Flexible production for structural engineering projects

Via importing the CAD, DSTV+ files into PROFILINE, the transition will be made to start the production. Sophisticated processes, such as sawing, drilling, milling, cutting and coping, will result in high-quality parts. Perfectly cleaned for manual welding, according to the ISO1090 standard. After welding, the complete constructions can be blasted and painted fully automatically, by means of the GIETART 3D Blaster and Top Coating line, incl. 3D Scanner. This integrated system enables to reduce your internal logistic and handling costs considerably.

Details

- Coping - KC 1221

- Painting - GIETART Top Coating 2512

- Plate Processing - KF 2614 / 28

- Band Sawing - KBB 1001

- Band Sawing - KBP 1001 (KBS 1051)

- Circular Sawing - KKS 463 NA

- Drilling - KDB 1015

- Drilling - KDP 1036

- Shot Blasting - GIETART ECO Blaster 1504

- Shot Blasting - GIETART 3D Blaster 3010

- Transport system

Transport system T15

Deutsch

Deutsch